Terengganu Silica Consortium (TSC) is committed to advancing sustainability in every facet of its operations. From its inception, TSC has diligently pursued environmentally responsible practices to ensure the preservation of natural resources and the well-being of surrounding communities. Through meticulous planning and innovative technologies, TSC strives to minimize its ecological footprint while maximizing efficiency and productivity. By prioritizing sustainable sourcing methods and implementing stringent environmental regulations, we safeguard fragile ecosystems and promote biodiversity conservation. Additionally, TSC is dedicated to fostering social equity by actively engaging with local stakeholders, offering employment opportunities, and investing in community development initiatives. Through transparent reporting and continuous improvement efforts, Terengganu Silica Consortium sets a benchmark for sustainable practices in the industry, demonstrating a steadfast commitment to environmental stewardship and societal progress.

Setting Standards with SBTI Approval

Terengganu Silica Consortium is proud to announce our ambitious commitment to combat climate change. Through rigorous efforts and strategic planning, we have set forth a Greenhouse Gas (GHG) emission, which has been officially approved by the Science Based Targets initiative (SBTi). Our goal is nothing short of remarkable: to achieve carbon neutrality by 2030 and ultimately reach Net Zero Emissions by 2050.

Read More

TRG Industrial Minerals Sdn Bhd (TIM), the holding company of Terengganu Silica Consortium (Setiu), TRG Silica Marang (Marang), and TRG Quartz Resources, is committed to reducing its GHG emissions, aligning with the SBTi to help achieve global climate goals.

TIM’s approved targets are designed to achieve significant reductions by 2030, aligning with the objective of keeping the global temperature rise well below 2°C, as outlined in the Paris Agreement. By implementing innovative strategies across its mining and production operations, TIM is driving sustainability in the silica mining sector.

SBTi Targets for 2030: We aim to reduce GHG emissions in three main scopes through a combination of energy efficiency, sustainable practices, and technological advancements. For more information, you may refer to https://sciencebasedtargets.org/companies-taking-action#dashboard

Targets

Scope 1 – Mobile & Stationary Equipment (Diesel) and Fugitive Refrigerants

- GHG Emission Reduction Target: 25% reduction by 2030

- Initiatives:

- Transition to electric-powered or hybrid mining equipment.

- Improved energy efficiency in diesel consumption for mobile machinery

- Reduction of refrigerant leaks and transition to lower GWP refrigerants.

Scope 2 – Purchased Electricity

- GHG Emission Reduction Target: 25% reduction by 2030

- Initiatives:

- Transition to renewable energy sources such as solar power for mining and production facilities.

- Energy-efficient upgrades in mining plants and administrative offices.

- Smart energy management systems to optimize electricity use.

Scope 3 – Upstream Transportation & Distribution

- Reduction Target: Measure and reduce its scope 3 by 2030

- Initiatives:

- Optimizing logistics and transportation routes for silica products.

- Collaboration with transport providers to adopt cleaner vehicles and reduce emissions from shipping and logistics.

- Digital solutions to track and minimize transportation emissions.

Malaysian Green Technology and Climate Change Corporation

TSC is audited by the MGTC – an agency of the Ministry of Natural Resources, Environment and Climate Change (NRECC) mandated to drive the country in the scope of Green Growth, Climate Change Mitigation and Green Lifestyle

TSC Green Tenets

Terengganu Silica’s Green Concept based on 5 Physical elements, which is the basis of all cosmic creation. TSC emphasizes strictly on the fundamentals of sustainability on leaving a footprint for future generations. The elements are Earth, Water, Energy, Air and Space.

Carbon Disclosure Project

TSC is also registered under CDP for GHG (Greenhouse gases) – Our commitment and yearly reporting shall be available publicly

First in Asia Electronic Dredger

Raw silica is extracted through our environmentally friendly electronic dredger and sent directly to our processing facility through High Density Polyethylene (HDPE) piping, resulting in zero contamination and pollution to the environment.

Efficient, Sustainable Mining Practices

The entire process is fully functional through various leading international accredited systems that have been put in place which focuses on productivity and efficiency from effective stockpile management to closed circuit water recycling system and customized spiral for higher separation and extraction of high purity silica.

Beneficiation Plant

Terengganu Silica has built a fully integrated and semi-automated mining, processing, stockpile and transportation complex. Our State of Art Beneficiation Plant based on Australian Technology adapting “Gravity Principles”, provisioned with customized equipment from reputable companies all over the world.

Terengganu Silica, the only green technology based silica beneficiation company in Asia & Oceania, successfully implemented the best practices in handling and transportation of silica sand. With 1km of slurry pipeline, 3.8km of pipe conveyor and the unique ship loading facility and a dedicated private port, we minimise the use of heavy machinery such as excavators, scrappers or trucks.

The Longest Automated Closed Pipe Conveyor in Asia and Oceania

The longest automated closed pipe conveyor is at 3.8km long and duly functions to eliminate any kind of contamination in silica distribution from the stockpile till unloading point at Terengganu Silica Port. Silica products are completely enclosed within the belt where pollution, environmental damage and dust are effectively controlled. The SCADA single system designed to exercise control and coordinate the integrated operation starts from Mining → Plant → Stockpile → Port.

Community Development

TSC’s initial investment of RM250mil has brought rapid socioeconomic changes into the less developed zones by uplifting the wellbeing of the community through various opportunities either directly or through spillover effect.

The Staff of TSC formed an in-house Club to carry out various community activities and with full support from the Management, as we believe in the concept “charity starts from home”

Community Development

TSC’s initial investment of RM250mil has brought rapid socioeconomic changes into the less developed zones by uplifting the wellbeing of the community through various opportunities either directly or through spillover effect.

The Staff of TSC formed an in-house Club to carry out various community activities and with full support from the Management, as we believe in the concept “charity starts from home”

Environmental Preservation

The Group has implemented various Project in-related to environmental preservation as part of its rehabilitation process in preserving mother nature.

TSC reduces CO2 emissions through various programs and recycles waste and water from its processes to prevent environmental contamination.

A meticulous planning on rehabilitation to address the post mining “physical change to landscape.”

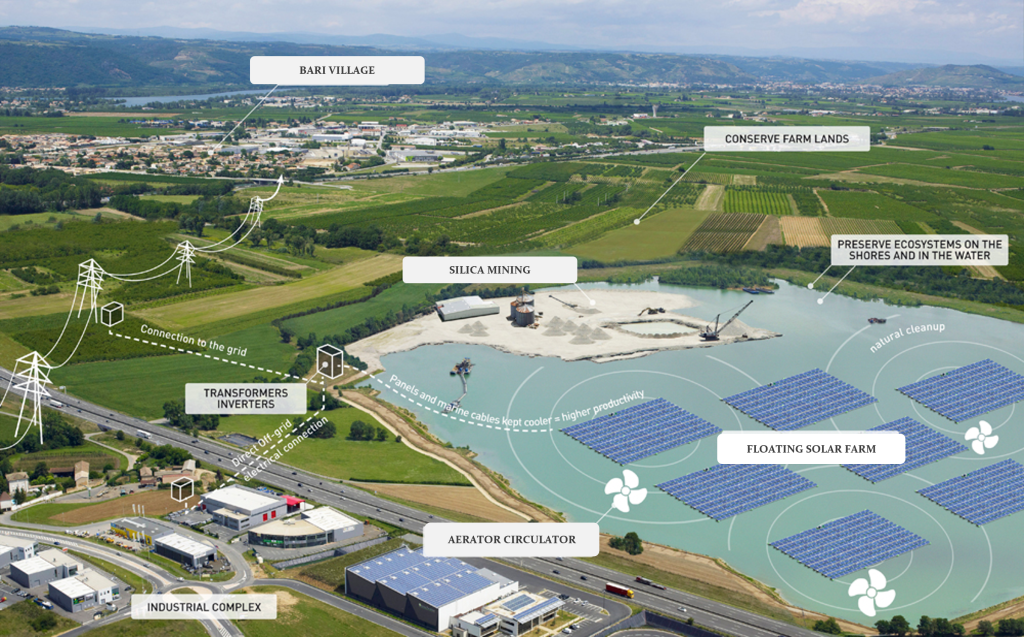

TSC is currently spearheading the “Floating Solar pilot project” as part of its on-going R&D.

Beach nourishment extends over a 3km stretch of coastline enhancing its shoreline and mitigating erosion. Rehabilitation programs including the introduction of additional native vegetation and beach cleaning to increase sea turtle nestling to produce more male offspring.

Marine Ecosystem, biodiversity and conservation

TSC incorporates smart technology, including wildlife-friendly lighting and establishes a cross-sector partnership with the Department of Fishery, Terengganu, SEATRU University Malaysia Terengganu and active involvement in Rantau Abang Sea Turtle Conservation under the Department of Fishery (Malaysia) supervision to support sea turtle conservation efforts and enhance the ecology and marine ecosystem in Pantai Bari, Setiu vicinity.

100% Malaysian

Throughout the years, TSC has employed more than 150 personnel locally and fully committed to being a 100% Malaysian company workforce.

Currently TSC is also conducting a recruitment campaign for its on-going expansion of its production capacity as well to the launching of new grade products with a projected job opening of over 60 employment opportunities, focusing on locals.

As part of an initiative and to strive as a “Caring Employer” TSC Management has provided various benefits to the staff as part of striving to be an “organization of choice” such as yearly medical health screening, fitness programs as well as staff insurance and dental to name a few.

Occupational Safety & Health is Everyone’s Business

Apart from government agencies and external courses and workshops, TSC’s Environment, Health & Safety as well Security Head of Departments ensure their departments always stay abreast of the latest developments and news of their own domain.